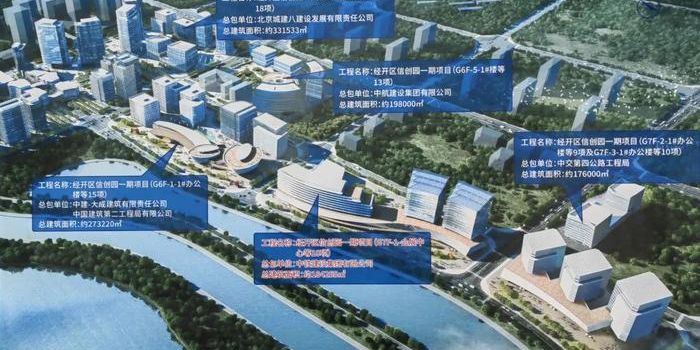

On June 25th, with the last large-span steel structure truss steadily rising and being lifted into position, the main steel structures of the five plots (G7F-2, G7F-3, G6F-1, G6F-5, G7F-1) of the National Information and Innovation Park Phase I project in Beijing Economic Development Zone, which were jointly constructed by China Construction Second Engineering Bureau Installation Engineering Co., Ltd. (hereinafter referred to as China Construction Second Engineering Bureau Installation Company), were fully capped, with silver gray metal lines outlining the dynamic and lightweight building skeleton, Spread out a city painting with a strong sense of technology.

The relevant person in charge of the installation company of China Construction Second Engineering Bureau said, “The five plots cover functions such as cultural and entertainment, scientific and technological office, and commercial supporting facilities, involving different types of building structures. A total of 38000 tons of steel structure installation and production are equivalent to the total steel consumption of the five Eiffel towers

The installation company of China Construction Second Engineering Bureau has undertaken a total of five plots of steel Structural engineering of the first phase project of the Information Innovation Park. Among them, the construction of the first plot (G6F-1) involves the installation of a large number of special-shaped structures. In order to achieve the design effect, the auditorium of Building 6 is all made of special-shaped steel structures, of which only the “V” shaped steel columns amount to more than 900 tons. The installation of 16 V-shaped inclined steel columns, as the top priority, has become the key and difficult point of the project construction. The project technical team leverages BIM intelligent construction technology to conduct 3D modeling of key nodes and construction difficulties during the construction process. Through the visual display of the model, the installation height and angle are accurately grasped. This not only controls the installation accuracy within 2mm, but also improves construction efficiency.

In the construction of land plots (G7F-2, G7F-3), steel components are complex and diverse. It is necessary to insert tens of thousands of steel components into the structure of “core tube superimposed steel frame”, which requires extremely high requirements for component welding and construction. In the end, the project technical team relied on BIM technology and the steel structure full lifecycle platform to control the entire installation process. Through the dynamic three-dimensional animation display and virtual construction testing of the steel structure full lifecycle platform, precise control of the installation process was achieved, and installation efficiency was also improved.

In addition, the project has also configured a unique “QR code” for each steel component, allowing the production, transportation, and installation process of each component to be digitized and informationized throughout the entire lifecycle of the steel structure platform, providing a guarantee for the intelligent construction of the project.

It is understood that the first phase of the Xinchuangyuan project is expected to be completed and delivered as a whole by the end of 2025. In the future, there will be six major industrial parks located here, including integrated circuit design park, software industry park, network security park, new computing park, new communication park, and data industry park, forming a unique scientific and technological innovation ecosystem of Tongming Lake with complete chain, ecology, and system, forming a new landmark of an industrial comprehensive new city and leading the construction of a world-class industrial comprehensive new city.

source:https://news.sina.cn/2023-06-29/detail-imyyxrup3765429.d.html